Material preparation procedures are commonly a critical requirement for product safety and conformity assessments/tests in many product compliance laboratories around the World.

The procedures are labour-intensive, repetitive, routine and tiring. Most importantly, nearly all products are required to go through such procedures. Hence, two-third (2/3) of workers carry various material preparation tasks within each laboratory or organization.

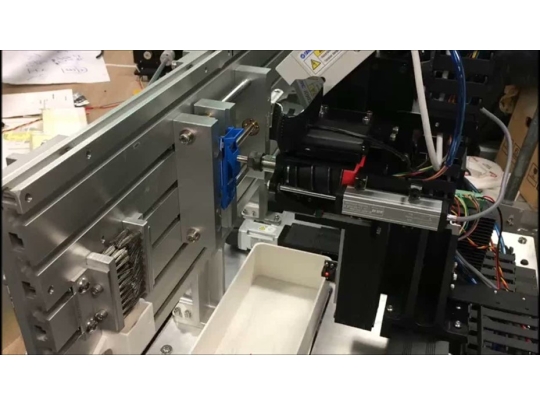

LSCM has developed a robotic material preparation device for product assessment. This robotic technology is comprised of tactile and visual guidance systems. In order to avoid cross-contamination, the device is designed to have an ionized air blower and a sample collection tank. In addition, a novel high-speed milling cutter was developed to effectively remove samples from the surface of selected items.

With the support of SGS, a renowned product safety and conformity assessment organization, this device can help prepare product samples of kitchenware, garment/clothing, woodware toys and so on for chemical or biological conformity assessments. These samples can be in different colours, shapes, sizes and made of various materials, all of which the robotic technology can handle.

The system is innovative as no similar device has been developed or used in the industry in Hong Kong. It improves cost effectiveness and enhances the competitiveness of local product safety, as well as conformity assessment standards.